By E.J. Daigle, Ed.D., Dean of Robotics & Manufacturing, Dunwoody College of Technology

Minnesota has long been a leader and innovator in the world of manufacturing – and educating the future workforce has been part of Dunwoody’s mission for more than a century. But if we want Minnesota to remain at the forefront of today’s high-tech, high-skilled, precision manufacturing industry, then we need to be just as innovative when it comes to attracting workers into the industry.

On Sunday, Star Tribune reporter and columnist Neil St. Anthony wrote about the long-term worker shortages in the manufacturing industry. I had the opportunity to speak with St. Anthony recently, when I was one of the panelists for a solutions-focused symposium on “Modern Manufacturing in Minnesota, Innovative Ways of Attracting and Developing New Talent.”

His article did a great job of highlighting how industry is taking a multi-pronged approach to solving this growing problem, and how schools like Dunwoody are stepping up to the challenge.

At Dunwoody, we know that skilled, manufacturing technicians are already in high demand. In fact, last May, we had 22.2 job inquiries PER graduate from our Machine Tool Technology and Right Skills Now for Manufacturing programs. And as St. Anthony points out in his article, Minnesota’s manufacturers pay among the highest hourly wages, with an average annual wage of around $65,000.

But while careers in manufacturing are high-paying and in high-demand, high school students are often not exposed to manufacturing as a career field The stigma of it as a “dirty” job still remains – even though it couldn’t be further from the truth.

Dunwoody is working with industry partners to help change that image, and several initiatives here at the College are having a positive impact.

Changing perceptions

From medical manufacturing to automated systems and robotics, the manufacturing industry is technologically advanced and changing rapidly.

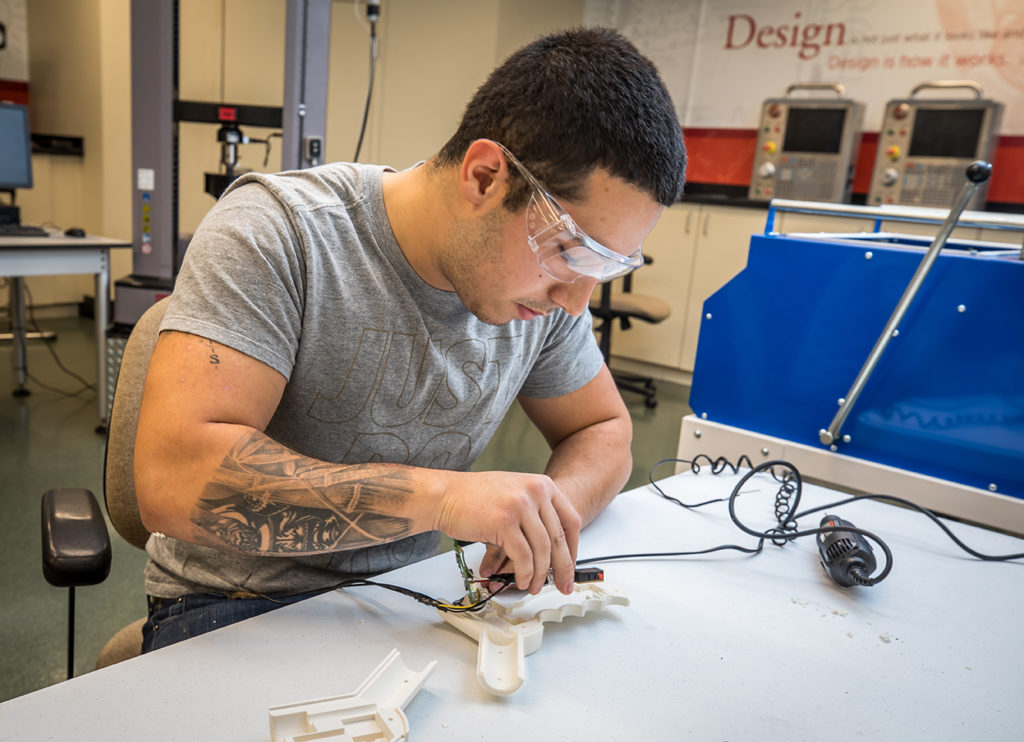

Students today are no longer just learning how to machine a part. They are designing the tools, programming the systems, and improving the process from start to finish. They are problem-solvers, innovators, and creators who are finding better-solutions to today’s problems.

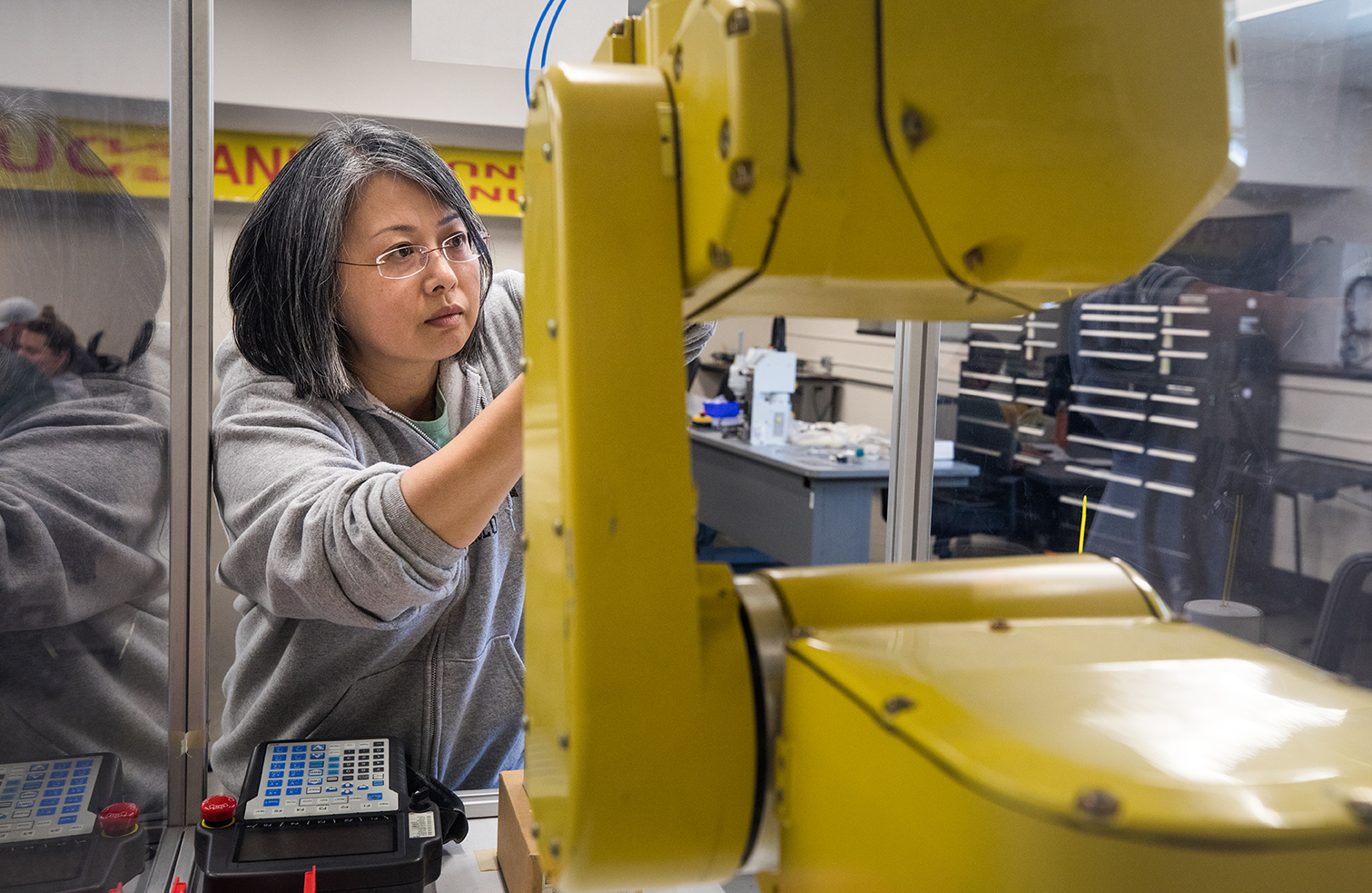

When potential students come to campus for a tour or an open house, they can explore the state-of-the-art industry tools, shops, and labs that students in the Robotics & Manufacturing department have access to. From programming robots to designing and making 3D-printed parts, today’s manufacturing is cutting edge and design-forward.

Much of the equipment found in our labs and shops is donated by industry partners, who are invested in ensuring graduates are ready to make a difference in the workplace – from their first day on the job.

Targeting students through scholarships

Driving more interest in manufacturing careers needs to start early. And initiatives like Dunwoody’s Youth Career Awareness Program helps accomplish that goal. The scholarship program provides an opportunity for high school juniors and seniors to spend several weeks during the summer here on campus, exploring different majors and career options and touring companies and future employers. Aimed at students from under-represented populations, the program has been successful in exposing more students to the great fields a Dunwoody education can prepare them for.

Dunwoody’s Women In Technical Careers scholarship program is also helping drive more women into non-traditional fields such as manufacturing. Women selected for the program are paired with an industry mentor during their time here at Dunwoody and receive professional development to help them become future leaders in the field.

Partnering with industry

Since its founding, Dunwoody has fostered partnerships with the industries it serves. Over the years, these partnerships have led to amazing opportunities for our students – that often begin long before graduation and employment.

Most of our manufacturing students take advantage of paid internships and part-time jobs, within the first year of the program. Regular interactions during company tours and on-campus networking opportunities allow our students to connect early and often with leaders in the manufacturing industry.

One of our partners, Boston Scientific, even nominated us for – and we received – this year’s Business of Manufacturing, Excellence in Training Award from Minneapolis/St. Paul Business Journal.

Preparing students for what’s next

The future of manufacturing also means preparing today’s workforce to be future leaders in the field. That’s why Dunwoody has structured stackable degree options, which allow students to move from a certificate, to a two-year associate’s degree, to a four-year bachelor’s completion degree. Options like this allow students to earn while they learn – and gain the leadership skills that will ensure Minnesota has the talent needed to remain a leader in the world of manufacturing for years to come.